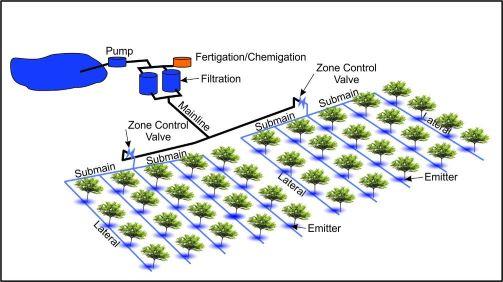

Core Components of a Typical Agricultural Micro Irrigation System

1. Water Supply

The water source can be:

- Open sources such as rivers, channels, dams, or tanks

- Groundwater sources such as bores or wells

2. Pump

The pump supplies energy to operate the system. When selecting a pump, consider:

- Operating pressure of micro emitters

- Friction losses in the pipes

- Elevation changes

- Losses from valves, fittings, and filters

- Allowances for system inefficiencies and ageing

A well-chosen pump ensures optimal efficiency and long-term performance.

3. Fertigation / Chemigation

- Fertigation allows soluble fertilisers to be applied through the irrigation system, with efficiencies of up to 90%.

- Chemigation involves injecting cleaning agents like chlorine or acid to flush contaminants from the system.

4. Filtration

Filtration is essential for removing debris from the water supply:

- Media filters are effective for open water sources with organic matter

- Disc or screen filters are common for groundwater with inorganic particles

Regular cleaning and maintenance (manual or automated) are essential for peak performance. Consult a certified irrigation designer to select the right filtration system.

5. Mainline

Transfers water from the source to the zone control valves. Usually made from:

- uPVC or PE (Polyethylene) pipes

- Designed to maintain flow velocities below 1.5 m/s

- Changes in direction should be thrust blocked (anchored with concrete)

6. Zone Control Valves

These valves control the flow to each irrigation zone and may be:

- Manual or automated (solenoid valves)

- Equipped with pressure regulators for consistent downstream pressure

- Paired with air/vacuum relief valves

7. Submain

Connects the mainline to lateral pipes. Typically:

- Made of uPVC or PE

- Connected using fittings such as Xpando Take-Offs

8. Lateral Pipework

Delivers water along the crop rows. Usually made of:

- Low Density Polyethylene (LDPE)

9. Emitters

Apply water directly to the root zone. Options include:

- Drippers

- Micro sprays

- Mini sprinklers

10. Flushing Points

Properly designed systems include flushing points to remove sediment and maintain water quality throughout the network.